Scheme Introduction

Based on the characteristics of chemical industrial parks, intelligent robots are used as the core to achieve autonomous patrol of various monitoring points in the park and detection and recognition of specific targets. Key areas and high-risk areas are inspected for personnel and environment, and management and monitoring of safety, environmental protection, energy consumption, and other aspects of the park are promoted more quickly, reducing labor costs and improving regulatory efficiency.

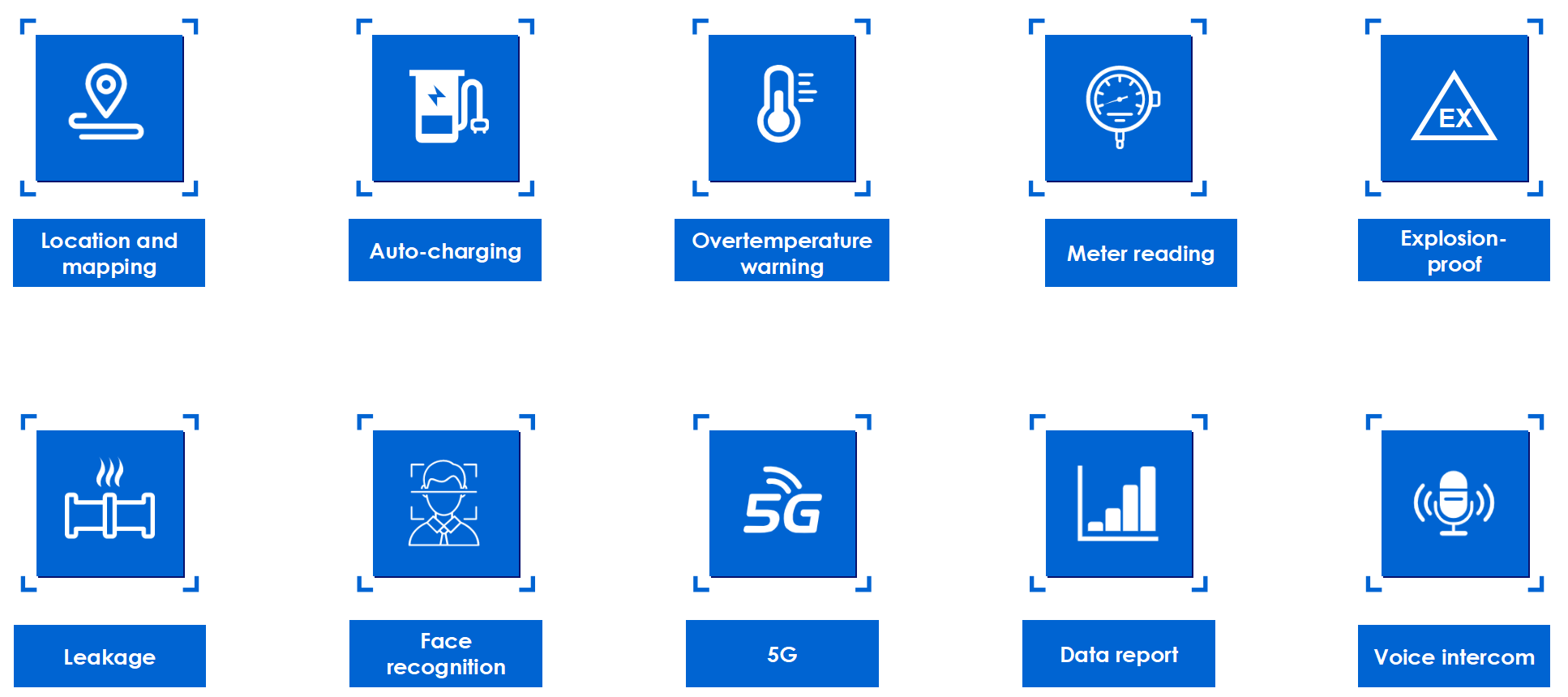

The inspection robot uses highly intelligent robot positioning, environmental modeling, navigation technology, and image recognition technology to replace manual labor in completing daily inspections of the park, infrared temperature measurement, instrument reading, gas leak detection, and equipment operation status detection and diagnosis, achieving full coverage inspection of the area. It has multiple functions such as security inspection, fire detection, environmental monitoring, smoke sensing, etc. It can effectively reduce safety hazards such as fires and suspicious personnel going out, improve the efficiency and quality of existing personnel inspections, alleviate the problem of weak power of duty personnel, and enhance work efficiency.

Pain Point Issues

Adverse and Harmful Environment

There are harmful environments such as toxic and harmful gases, dust, noise, etc., and it is not suitable for people to work in them for a long time.

Low inspection quality

Traditional inspections are mostly carried out manually, which has significant problems such as large data errors and high management costs.

High labor costs

Multiple shifts of inspection personnel are required, labor costs are increasing year by year, the industrial environment is harsh, and there are situations such as labor shortages and limited resources.

Core Functions