Scheme Introduction

In order to meet the increasing inspection requirements of gas companies, the latest technology and achievements of artificial intelligence have been innovatively utilized. Based on an advanced mobile robot platform system, flexible and convenient inspection robots are used to assist gas companies in daily inspection tasks of gas stations, achieving functions such as meter recognition, infrared temperature measurement, gas leak detection, sound analysis, and high-definition video monitoring. No need to modify existing gas equipment and facilities, no need to install any additional devices, can replace manual completion of most inspection tasks, and has the characteristics of high work efficiency, no fatigue, and stable inspection quality.

At the same time, the combination of fixed point monitoring and AI intelligent video analysis can achieve environmental inspection, fire hidden situation investigation, suspicious personnel detection, etc. in key and high-risk areas of gas stations, and accelerate the digital and intelligent development of gas stations.

Pain Point Issues

There are many safety hazards

The discovery of fault problems relies on manual labor, and some hidden dangers or faults are difficult to detect with the naked eye, which cannot provide real-time warning or early detection of problems, posing safety hazards.

Low inspection quality

There are problems with manual inspection, such as high labor intensity, inability to guarantee inspection quality, and low degree of informatization of paper inspection records.

High labor costs

Multiple shifts of inspection personnel are required for a single station, and the labor cost is increasing year by year. In addition, the intensity of manual inspection work is high, and there are problems such as labor shortage and limited resources.

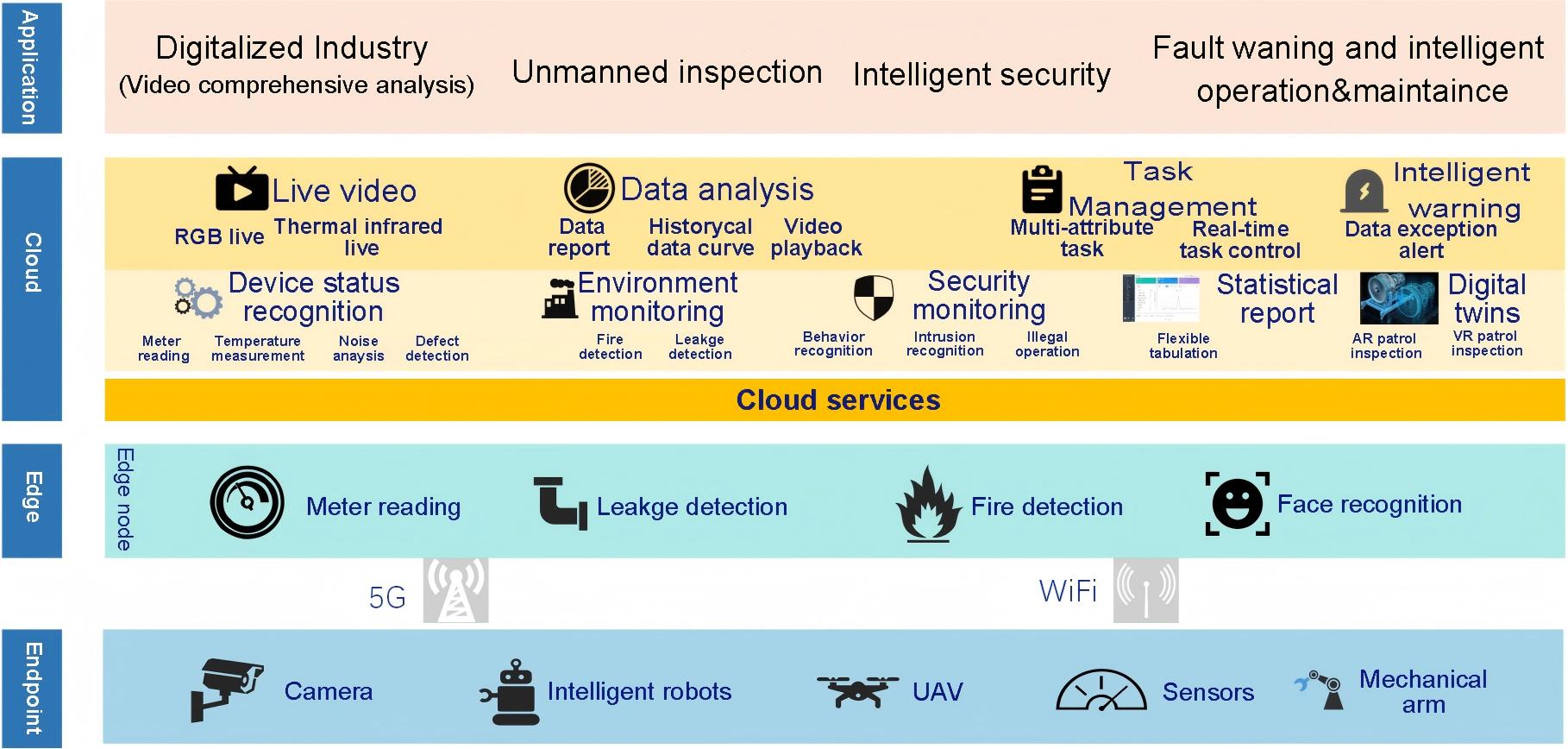

System Architecture

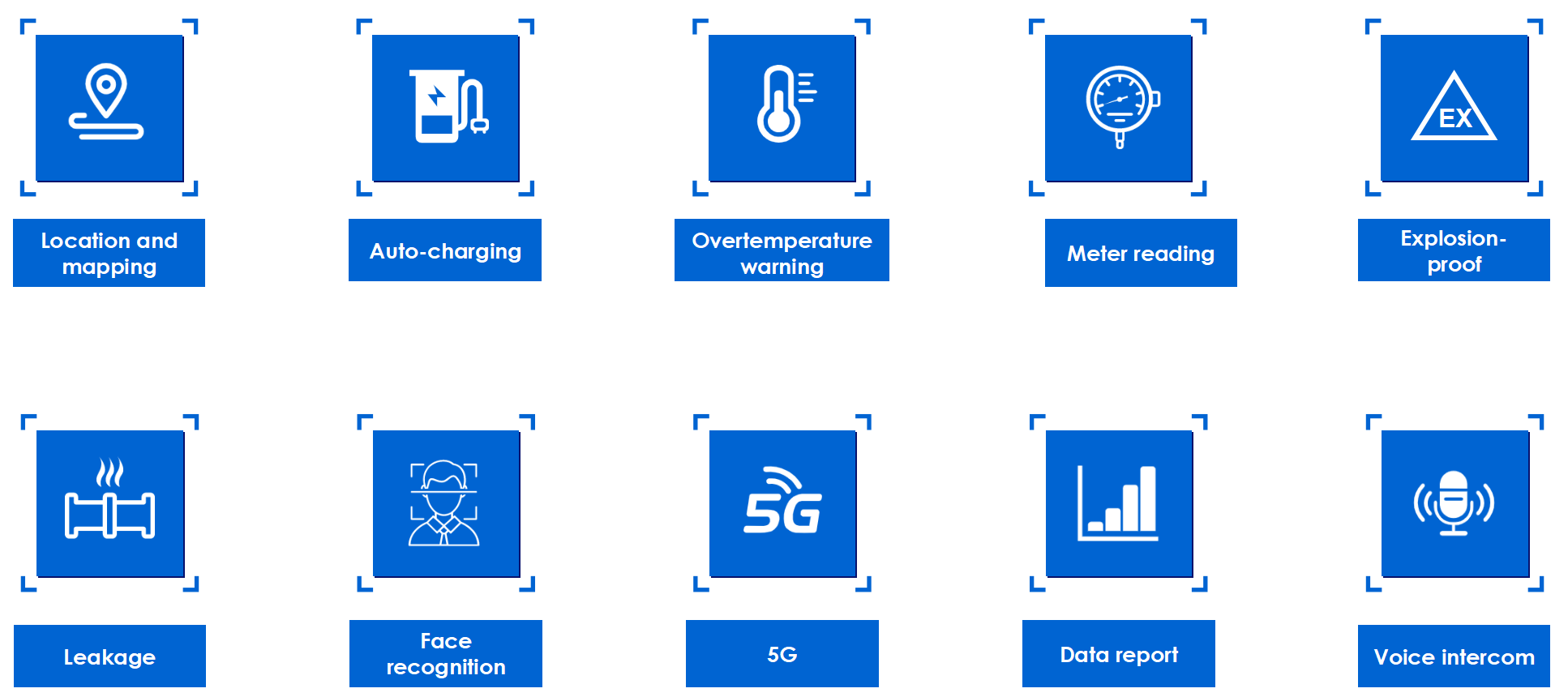

Core Functions