Scheme Introduction

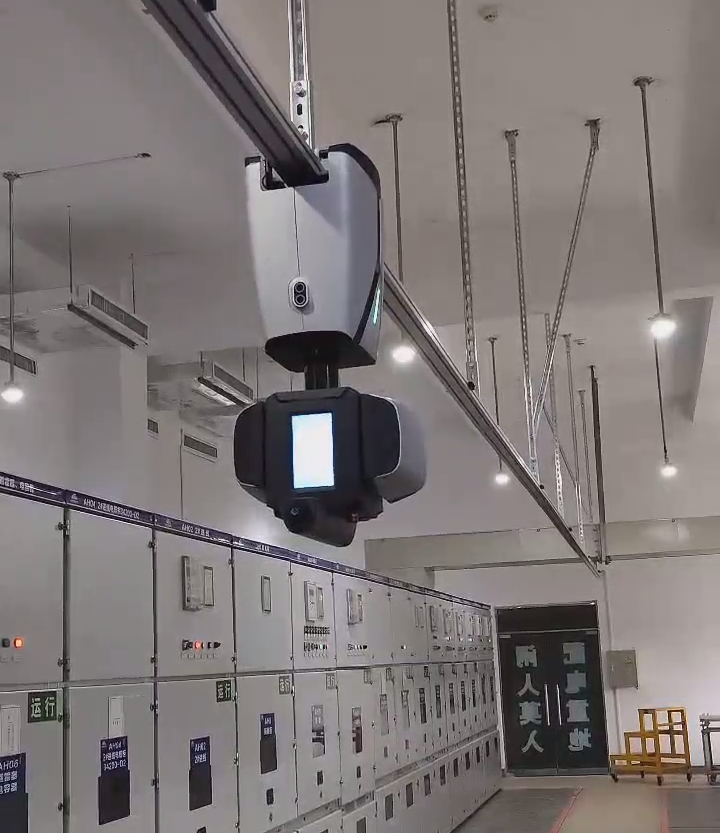

Based on the characteristics of the power industry, we provide intelligent robot solutions for substations, distribution stations, and other areas. With intelligent robots as the core, we can achieve autonomous detection of equipment, conduct equipment inspections in key and high-risk areas, and accelerate the process of digital and intelligent development.

Inspection robots use highly intelligent robot technology and image recognition technology to replace manual detection and diagnosis of equipment operation status in special environments, achieving full coverage inspection of equipment areas. They have multiple functions such as security inspection, environmental monitoring, smoke sensing, etc., which can effectively reduce safety hazards such as fires and theft, alleviate the problem of weak power of duty personnel, and improve work efficiency.

Intelligent robots can achieve functions such as intelligent recognition of meters, infrared temperature measurement, gas detection, vibration detection, sound analysis, high-definition video monitoring, etc., fully covering the monitoring of key equipment status, enabling operation and maintenance personnel to timely control the operation status of equipment.

Pain Point Issues

The manual inspection process is not traceable

The quality of inspection varies greatly due to the different qualities of personnel, and the accuracy of inspection data also varies.

There are hazards in the inspection environment

Some inspection areas have hazardous environments that pose a threat to personnel safety.

Low efficiency of manual inspection

The traditional manual inspection method has high labor intensity and low work efficiency.

Core Functions