Scheme Introduction

Based on the characteristics of the oilfield industry, we provide an intelligent robot solution for oilfield inspection. With intelligent robots as the core, we achieve autonomous detection of the well environment and equipment, and carry out equipment inspection in key and high-risk areas of the well area. This will accelerate the digitalization and intelligent management level and development process of oilfield well areas.

The inspection robot uses highly intelligent robot technology and image recognition technology to replace manual inspection and diagnosis of equipment operation status in special environments, achieving full coverage inspection of equipment areas. It has multiple functions such as meter recognition, equipment status recognition, infrared temperature measurement, environmental monitoring, oil and gas leakage detection, video live streaming, etc. It can effectively reduce safety hazards such as equipment shutdown, oil leakage, fire, theft, etc., alleviate the problem of weak power of duty personnel, and improve work efficiency.

Pain Point Issues

There are many safety hazards

Traditional manual inspection has problems such as high labor intensity, high level of danger, and inability to detect equipment hazards in a timely manner.

Poor Inspection Quality

Inspection personnel need to have professional skills and a high sense of responsibility, but they are prone to fatigue and slackness, and the quality of inspection cannot be guaranteed.

High User Costs

Difficulty in recruiting workers and continuously rising labor costs.

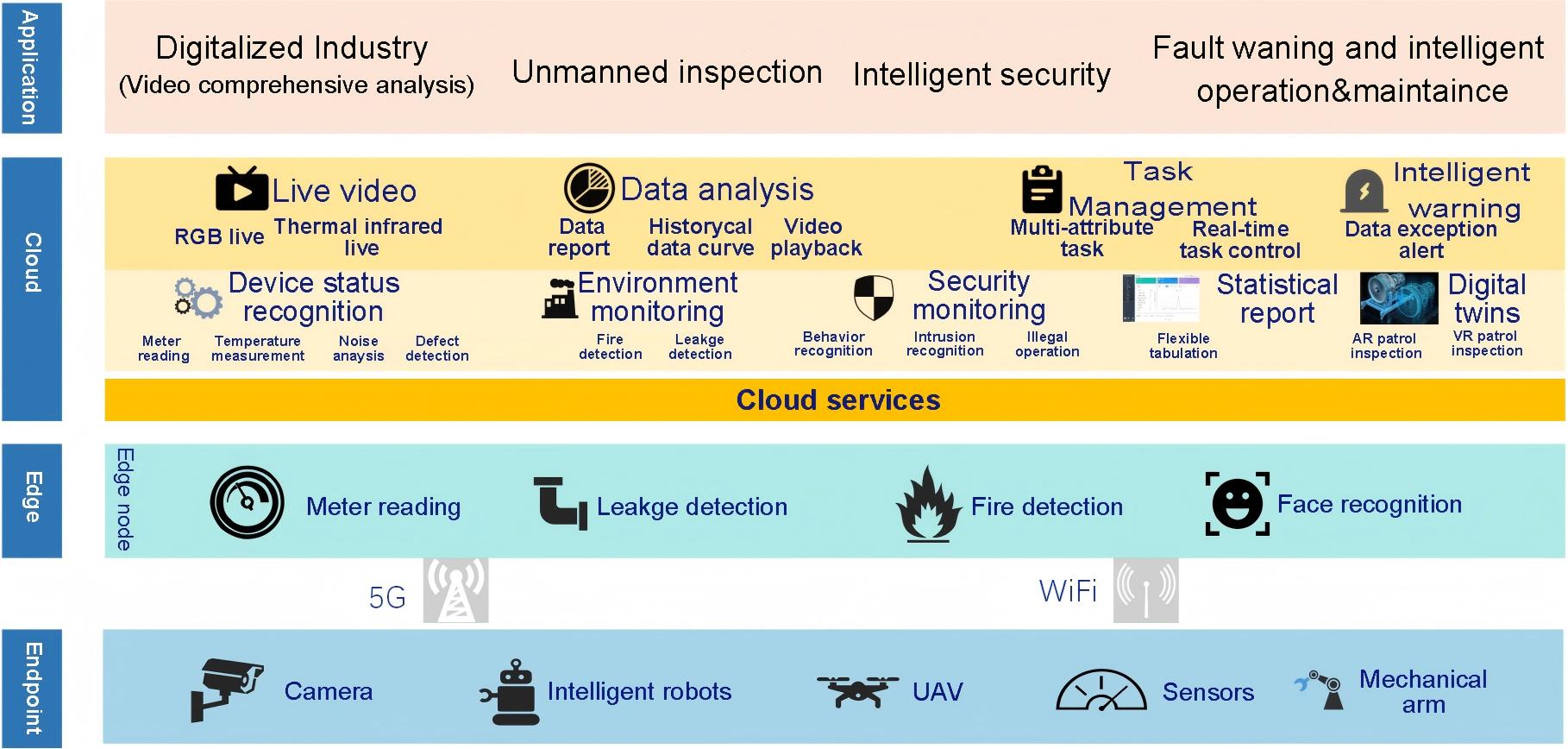

System Architecture

Core Functions